The law on lifts in bocks of flats is clear. You must have lifts inspected twice yearly. The HSE guidance on the Lifting Operations Lifting Equipment Regulations 1998 (LOLER) can be seen here1.

Also, regulations under The Health and Safety at Work Act 1974 make it clear that lifts must be marked to indicate safe working loads and be inspected by a competent person every six months.

As part of the one-stop shop service offered by Deacon we can help arrange independent inspections2 through a third party and provide cover to help meet the costs of sudden or unforeseen breakdowns.

Once the essentials are in hand, you have time to wonder about these machines that we take for granted work.

Just press a button and you’re transported.

Up and down, we put a lot of trust in lifts, or elevators as they are often referred to across the pond, but rarely give a second thought to how they work.

Of course, we have the reassurance of laws which require regular maintenance and safety checks, but have you ever considered what goes on outside the box?

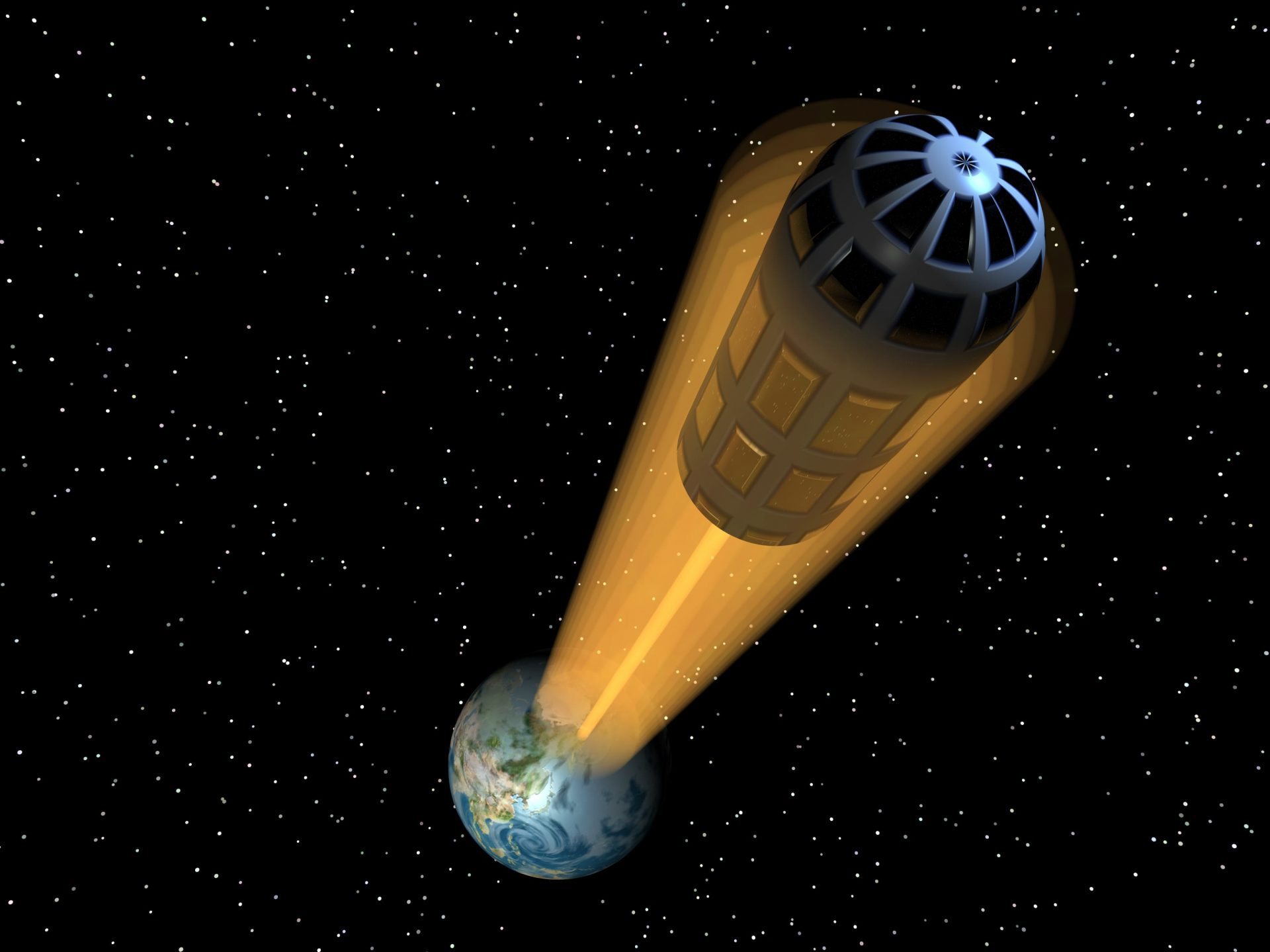

Lifts that can zoom up beyond Earth have certainly captured people’s imagination in the decade or so since space scientists first proposed them—and it’s no wonder. But in their time, ordinary building lifts probably seemed almost as radical.

It wasn’t just brilliant building materials such as steel and concrete that allowed modern skyscrapers to soar to the clouds. It was the invention, in 1852, of the safe, reliable elevator by a man named Elisha Graves Otis of Yonkers, New York.

Elisha Graves Otis3 literally changed the face of the Earth by developing a machine he humbly called an ‘improvement in hoisting apparatus’, which allowed cities to expand vertically as well as horizontally.

The most popular elevator design today is the roped elevator, where the car is raised and lowered by traction steel ropes. At its simplest, the ropes are attached to the elevator car at one end, looped around a pulley system, and connected to a counterweight at the other end.

The heavy counterweight weighs roughly the same amount as the car when it’s loaded half-full (in other words, the weight of the car itself plus 40–50 percent of the total weight it can carry). So when you press a button and the elevator goes up, the counterweight goes down—and vice-versa.

There are abundant safety systems to stop the Hollywood-scenarios of lifts plummeting to the ground. As well as multiple steel ropes, each of which could support the weight on its own, there are governors to stop the elevator moving too fast and automatic braking systems near the top and the bottom of the lift shaft.

Skyscraper challenge

Designers of skyscrapers and ‘vertical cities’ face a conundrum with lifts. You need a lot of them to transport volumes of people quickly enough to make the building efficient; but lots of lift shafts take up lots of valuable space.

So, speed and capacity have been their first challenge. The 632m Shanghai Tower3, one of the world’s tallest buildings, has an elevator that travels at 40+ mph.

Now engineers are looking at new ropeless elevators4, technology that uses magnets instead of cables to create lifts that can travel vertically, horizontally and, possibly as decorative features on the outside of a building so they don’t use up valuable space inside.

There’s even a concept for an elevator taking you into space5.

Reviewed 20 July 2022

FP883-2017

The opinions and views expressed in the above articles are those of the author only and are for guidance purposes only. The author disclaims any liability for reliance upon those opinions and would encourage readers to rely upon more than one source before making a decision based on the information.